Put to the test

A technical solution’s quality can only be demonstrated by pushing it to its limits. KSB therefore puts all products through their paces via challenging test scenarios before launching them to market and shipping them to customers. With customers around the globe placing their trust in KSB’s reliable quality, the company ensures that testing is carried out to the same high standards at all test facilities worldwide. Some 28,000 pump tests are carried out every year at 50 test facilities KSB-wide.

1

China

Two KSB Shanghai Pump Co., Ltd. employees at the test stand

“Pump performance testing is the most important phase in ensuring the quality of the final processes, including

materials, machining and installation. It also plays a fundamental role in demonstrating KSB’s technology and

product quality to our customers,” says Hongwu Zhu, who heads the test facility at KSB Shanghai Pump Co., Ltd.

The facility’s 16 specialists and cutting-edge test stand ensure that performance testing of KSB pumps is carried out in accordance with international standards. Online acceptance tests have now become routine.

“Performance testing is a core process within pump manufacturing. The provision of performance-tested pumps is not just a customer requirement, it is part of KSB’s obligation to deliver consistently high product quality to our customers,” confirms Zhu.

Our SEC-KSB plant in China is also home to one of the KSB Group’s largest test facilities, built for testing reactor coolant pumps of all generations. This test stand can simulate the complete life cycle of such a pump – a process which has already taken place several times, including when testing the RUV series for Chinese nuclear power plants.

The facility’s 16 specialists and cutting-edge test stand ensure that performance testing of KSB pumps is carried out in accordance with international standards. Online acceptance tests have now become routine.

“Performance testing is a core process within pump manufacturing. The provision of performance-tested pumps is not just a customer requirement, it is part of KSB’s obligation to deliver consistently high product quality to our customers,” confirms Zhu.

Our SEC-KSB plant in China is also home to one of the KSB Group’s largest test facilities, built for testing reactor coolant pumps of all generations. This test stand can simulate the complete life cycle of such a pump – a process which has already taken place several times, including when testing the RUV series for Chinese nuclear power plants.

2

South Africa

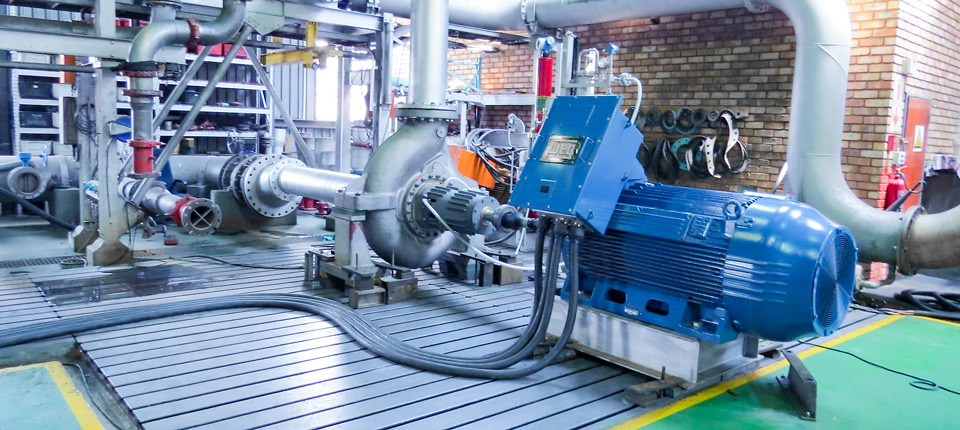

Remote acceptance testing is part of the routine at KSB Pumps and Valves (Pty) Ltd.

Based in Germiston, KSB Pumps and Valves (Pty) Ltd. operates several test facilities including a test stand in

Pretoria for large pumps which is run in partnership with the South African Bureau of Standards (SABS).

At the test facilities in Johannesburg, seven employees are responsible for operating two test stands and – as in almost all KSB test facilities – online acceptance testing in accordance with specified KSB standards is part of the routine.

Certain parts of the old test facility, which was built in the early 1970s and has a nine-metre-deep underground storage tank, are still used today on the modern test stand. Tests tailored to customer requirements, especially those using customer motors at different voltages, are very much in demand here.

Test stands are also available for standard tests, which are fully automated and equipped with multiple test loops.

At the test facilities in Johannesburg, seven employees are responsible for operating two test stands and – as in almost all KSB test facilities – online acceptance testing in accordance with specified KSB standards is part of the routine.

Certain parts of the old test facility, which was built in the early 1970s and has a nine-metre-deep underground storage tank, are still used today on the modern test stand. Tests tailored to customer requirements, especially those using customer motors at different voltages, are very much in demand here.

Test stands are also available for standard tests, which are fully automated and equipped with multiple test loops.

3

Germany

Dr Vanessa Romero Segovia from Model-based Product

Development at the Frankenthal development test stand

In Germany, KSB’s largest test facility for dry-installed water transport pumps is situated at our Halle location, and the largest test facility for boiler feed

pumps is located in Frankenthal. Both of these test stands offer variable speed tests

with and without the customer’s motor and with all necessary auxiliary units.

Frankenthal is also home to the central development test facility with more than 60 test stands able to test products from all production locations. “Throughout KSB, we have the unique ability to implement time-intensive and application-specific tests such as hot water and hot oil tests, or low-temperature tests down to minus 20 °C,” explains Andreas Karsch, Head of Testing Engineering.

“We want to get the most out of our pumps,” says Karsch. “We are essentially the competence centre for KSB’s test stand technology. We design and build test stands, create central KSB standards – for online acceptance tests for example – and develop KSB’s in-house software for data acquisition on all KSB test stands worldwide.” Continuous, cutting-edge development of testing options and thus of KSB products is ensured thanks to the work of more than 30 staff and numerous students who always bring fresh ideas, as well as cooperations with multiple universities. “This is what we stand for. And our know-how is available to the entire KSB Group,” underlines Karsch.

Frankenthal is also home to the central development test facility with more than 60 test stands able to test products from all production locations. “Throughout KSB, we have the unique ability to implement time-intensive and application-specific tests such as hot water and hot oil tests, or low-temperature tests down to minus 20 °C,” explains Andreas Karsch, Head of Testing Engineering.

“We want to get the most out of our pumps,” says Karsch. “We are essentially the competence centre for KSB’s test stand technology. We design and build test stands, create central KSB standards – for online acceptance tests for example – and develop KSB’s in-house software for data acquisition on all KSB test stands worldwide.” Continuous, cutting-edge development of testing options and thus of KSB products is ensured thanks to the work of more than 30 staff and numerous students who always bring fresh ideas, as well as cooperations with multiple universities. “This is what we stand for. And our know-how is available to the entire KSB Group,” underlines Karsch.

KSB’s Brazilian factory in Várzea Paulista is home to one of the largest and most versatile test facilities in

Latin America. It features nine test stands which can be configured to test almost every type of KSB pump as well

as pumps repaired by our KSB SupremeServ. A further test stand for submersible motor pumps is located at the Jundiaí plant.

“The department responsible for the test stands plays a fundamental role in the company, as it can guarantee the quality and functionality of KSB products and thus provide added value for our customers. Services in the field of testing are increasingly requested and purchased by our customers. Key account customers see performance testing as an important and essential requirement,” explains Thiago Munhoz, an employee at the test facility in Várzea Paulista. “During the pandemic, our department faced major challenges. A lot of testing normally done in person with the customer had to be performed via video conferencing during this period.”

“The department responsible for the test stands plays a fundamental role in the company, as it can guarantee the quality and functionality of KSB products and thus provide added value for our customers. Services in the field of testing are increasingly requested and purchased by our customers. Key account customers see performance testing as an important and essential requirement,” explains Thiago Munhoz, an employee at the test facility in Várzea Paulista. “During the pandemic, our department faced major challenges. A lot of testing normally done in person with the customer had to be performed via video conferencing during this period.”

4

Brazil

KSB’s Brazilian factory in Várzea Paulista is home to one of the largest and most versatile test facilities in

Latin America. It features nine test stands capable of testing almost every type of KSB pump, as well as pumps

repaired by the company’s own KSB SupremeServ.

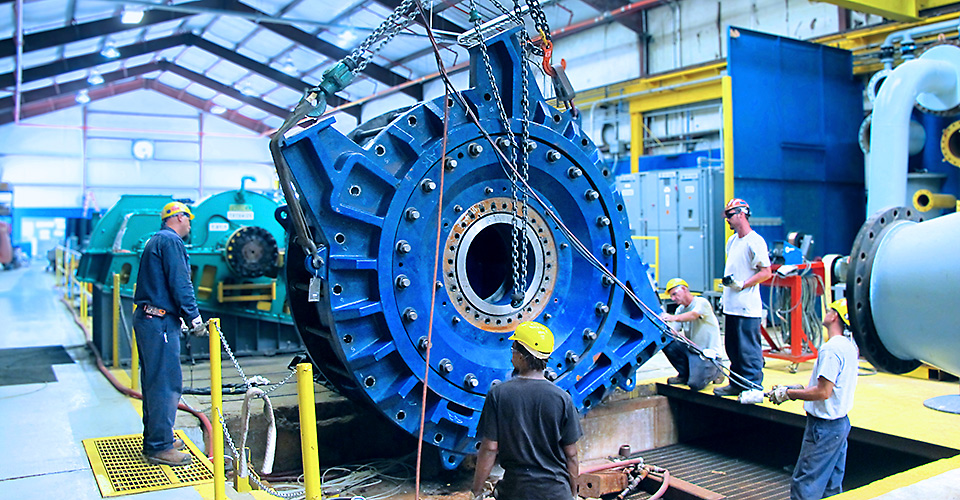

5

USA

GIW pumps transport highly abrasive slurries.The hydraulics laboratory is globally unique in its capacity to

handle pump performance testing and slurry testing.

GIW pumps convey highly abrasive solids. “The GIW hydraulics laboratory is globally unique in its capacity to

handle pump performance testing and slurry testing. On the one hand, it is able to verify the performance of pumps

with impeller diameters of up to 2.87 metres. On the other, it has the expertise to test slurries in pipelines of

any size,” reports George McCall, who heads the hydraulics laboratory at GIW. Eleven employees ensure that the

pumps are put through their paces.

The test stands are primarily intended for testing pumps typically manufactured by GIW Industries, Inc.: end-suction, single-stage centrifugal pumps for slurries. However, they can also be configured to test any pump.

The test stands are primarily intended for testing pumps typically manufactured by GIW Industries, Inc.: end-suction, single-stage centrifugal pumps for slurries. However, they can also be configured to test any pump.

The Indian locations Shirwal, Chinchwad, Pimpri and Sinnar all have test facilities.

“We manufacture a variety of pumps that we subject to a range of tests,” says Nitin Patil, who manages the test

facility in Chinchwad.

“In recent years, we have successfully developed and tested new pumps,” Patil explains. “The key function of the test stands is proving the performance of the final product before we ship it to our customers. They confirm our guaranteed performance to the customer and any discrepancies can be corrected. This strengthens our customers’ trust in our quality and reliability.”

“In recent years, we have successfully developed and tested new pumps,” Patil explains. “The key function of the test stands is proving the performance of the final product before we ship it to our customers. They confirm our guaranteed performance to the customer and any discrepancies can be corrected. This strengthens our customers’ trust in our quality and reliability.”

6

India

Test stands are operated at the Indian locations in Shirwal, Chinchwad, Pimpri and Sinnar.